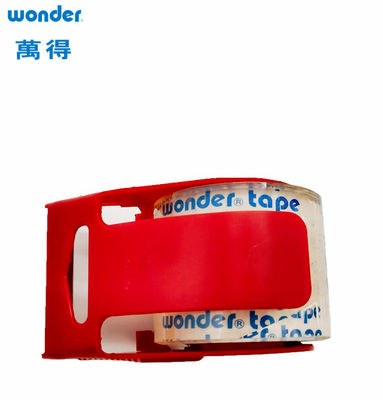

Wonder HP102 Model Type Tape Cutter Dispenser For Water Based Acrylic Adhesion General Packaging Tape Easy packaging

Description:

1.Blade Options: The blades used in tape cutters can vary in material and design. Most tape cutters feature sharp, replaceable blades made of stainless steel or high-carbon steel. Some blades are straight and smooth, while others have serrations or teeth to enhance cutting performance on specific tape types.

2.Safety Features: Many tape cutters incorporate safety features to minimize the risk of accidents. For example, some cutters have retractable blades that are only exposed when pressure is applied to the tape, reducing the chances of accidental cuts. Others have blade guards or shields that cover the blade when not in use, preventing contact with the sharp edge.

3.Tape Width Adjustment: Some tape cutters offer adjustable features to accommodate tapes of different widths. They may have guides or mechanisms that allow users to set the desired tape width, ensuring precise and consistent cuts regardless of the tape size.

4.Tape cutters are commonly used in various industries and settings where tapes are frequently used, such as shipping and packaging, arts and crafts, construction, and office environments. They are especially useful in scenarios where precision and efficiency are required, as they enable quick and accurate tape cutting, saving time and effort.

5.It's important to note that tape cutters should be handled with care due to their sharp cutting edges. Proper safety precautions should be followed to prevent accidents or injuries while using them.

Application:

1.Office and Stationery: Tape cutters find everyday use in office and stationery environments. They simplify tasks such as sealing envelopes, attaching documents, or taping packages. Tape cutters with built-in dispensers are particularly useful, allowing for one-handed operation and smooth tape application.

2.Manufacturing and Industrial Settings: In manufacturing and industrial settings, tape cutters are employed for a wide range of applications. They are utilized for cutting tapes used in product assembly, securing components, bundling items, or marking areas. Industrial tape cutting machines may be employed for high-volume production environments, providing accurate and rapid tape cutting capabilities.

3.Automotive and Electronics: Tape cutters are used in automotive and electronics industries for tasks like wire harnessing, cable management, and component assembly. They enable precise cutting of adhesive tapes for securing and insulating wires, mounting components, or protecting sensitive electronic parts.

4.In medical and healthcare settings, tape cutters are used for cutting medical tapes used in wound dressings, bandages, or surgical applications. They ensure clean and controlled cuts, minimizing the risk of tissue damage or discomfort for patients.

5.Arts and Crafts: Tape cutters are handy tools in arts and crafts projects. They help with precise taping and mounting of materials such as paper, cardstock, or photos. Whether it's scrapbooking, card making, or other craft activities, tape cutters enable clean and accurate cuts of decorative tapes, double-sided tapes, or masking tapes.

6.Construction and Home Improvement: In construction and home improvement projects, tape cutters are used for various tasks. They assist in cutting adhesive tapes like duct tape for temporary repairs, masking tape for painting or taping off surfaces, or electrical tape for securing and insulating wires. Tape cutters ensure clean and straight cuts, making these projects more efficient.

Technical information:

Advantage:

1.Waste Reduction: Using a tape cutter helps minimize waste by enabling precise cutting of tape lengths according to specific requirements. This reduces unnecessary tape usage and minimizes material waste, making tape cutters environmentally friendly choices.

2.Cost-Effective: Tape cutters can contribute to cost savings in various ways. By eliminating the need for additional tools like scissors or blades, they reduce the expenses associated with replacing or maintaining those tools. Moreover, efficient tape cutting with a tape cutter can help optimize tape usage, reducing the frequency of tape replenishment.

3.Clean and Neat Appearance: Tape cutters help achieve a clean and neat appearance in various applications. Whether it's sealing packages, taping down cables, or mounting materials, tape cutters ensure precise cuts, resulting in tidy and professional-looking outcomes. This is particularly important in industries where aesthetics and presentation are crucial, such as retail, events, or photography.

4.User-Friendly: Tape cutters are designed to be user-friendly, even for individuals without specialized training or experience. They typically have intuitive mechanisms or features that make them easy to use. With minimal effort, users can operate tape cutters efficiently, allowing for seamless integration into different workflows and tasks.

5.Reduced Fatigue: Using tape cutters reduces hand and finger fatigue compared to manual cutting methods like tearing or using scissors. Many tape cutters feature ergonomic designs and comfortable grips, enabling users to perform repetitive cutting tasks for extended periods without strain or discomfort.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!